Introduction

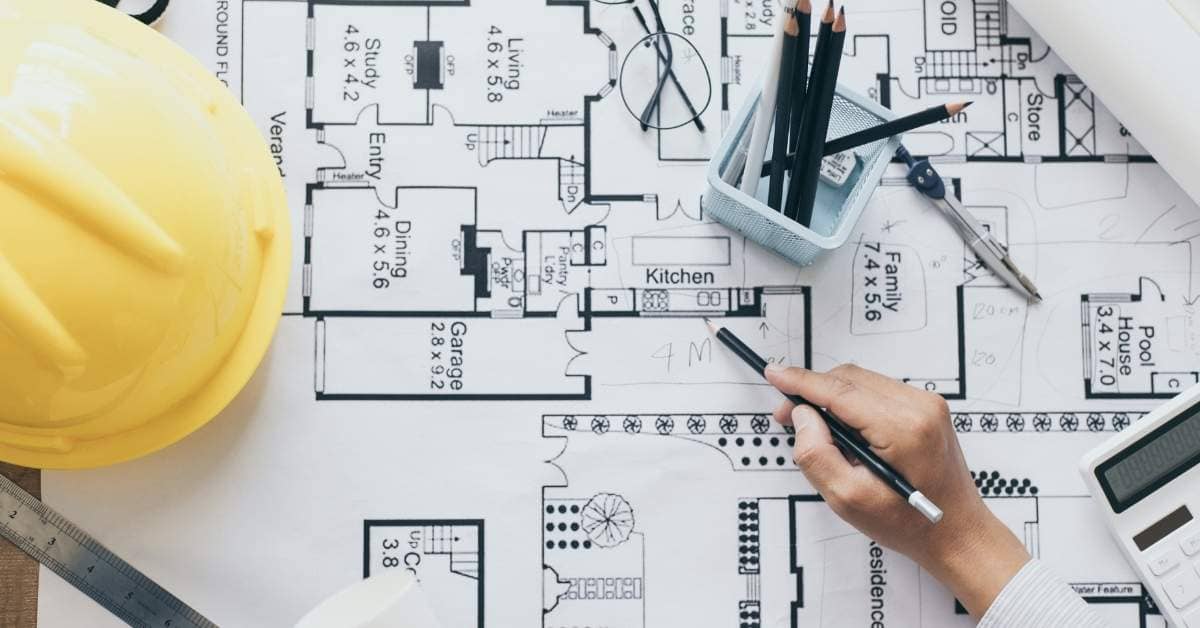

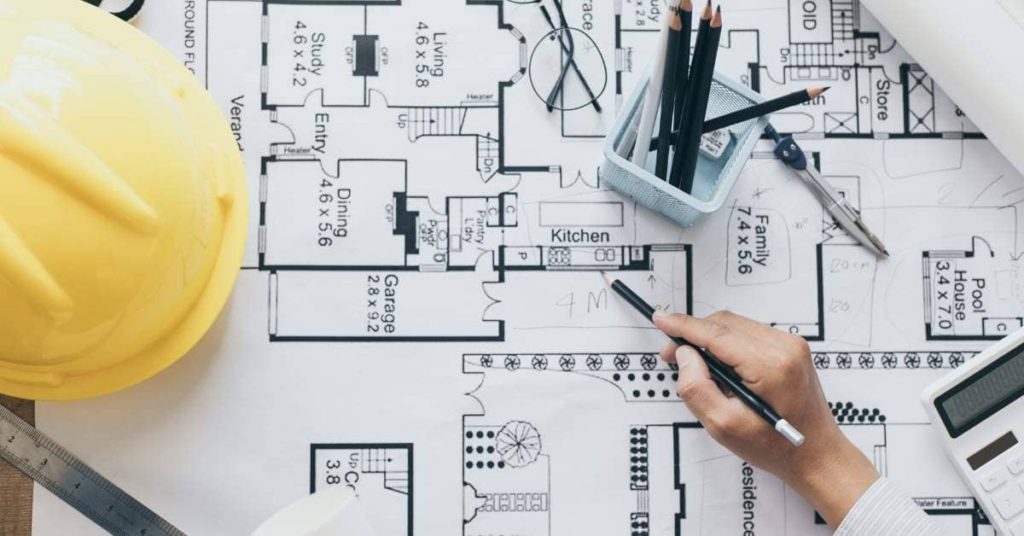

Detailed engineering drawings are an important part of product development, design, and manufacturing. Without these blueprints and specifications, design teams would be unable to communicate or work together on the same product at the same time. Detailed engineering drawings help us communicate a product’s design intent to all stakeholders involved.

Detailed Engineering Drawings?

A detailed engineering drawing is a technical drawing that shows all the dimensions, tolerances, and other requirements for manufacturing a part. It’s used by engineers and designers to create parts and assemblies.

The major purpose of engineering drawings is to provide precise instructions for manufacturing parts or creating assemblies. They can also be used as a basis for cost estimates, quality control checks, and other functions.

Detailed engineering drawings are created in CAD programs such as Solid Edge or AutoCAD Inventor. These programs allow you to create more accurate drawings than hand-sketched sketches because they let you use precise measurements instead of using just lines and arcs with no fixed widths or lengths—you can draw perfect circles with widths measured in millimeters! The ability to easily change the size of objects on-screen allows you to make sure your parts will fit together before you start making them so there’s less wasted time chasing problems later on down the road when things aren’t fitting right offhand–which saves money!

Prepare an Engineering Drawing

An engineering drawing is a visual representation of a product, its parts and assemblies, and its dimensions. It shows how the product should be constructed in order to meet specifications. Engineering drawings are used to guide the design process and manufacturing process of new products or repairs.

A variety of different types of engineering drawings exist:

- Assembly Drawing– Includes all components necessary for assembly including hardware, fasteners, adhesives, and any other materials needed for assembly (screws, bolts). Also includes dimensional information such as tolerance stack-up.

- Bill Of Materials Drawings (BOM)– Lists all parts by part numbers/names along with the quantity required per part number/name on an assembly drawing or product drawing. It also provides information about each part such as manufacturer’s name, material type (for example plastic), color code if applicable, etc…

- This type of document is sometimes referred to as a “Detail Schedule” when it does not include specific sizes or tolerances associated with individual items listed within its contents section but rather just lists them by family name instead; however, these two terms are interchangeable depending upon what type of project you’re working on at any given time so don’t worry too much about getting confused over these distinctions!

Engineering Drawing Tools & Techniques

The tools and techniques used to create detailed engineering drawings can be broken down into three categories:

- Drawing standards for engineering drawings. The drawing standards defined by the American Society of Mechanical Engineers (ASME) are used worldwide and have been adopted by many industries. They incorporate a set of rules for creating certain types of drawings that apply to all types of mechanical design and manufacturing projects. This includes specifications for how diagrams should be laid out, what format they should take (such as isometric or orthographic), and what symbols should be used in each case. There are also guidelines on how much detail should go into certain aspects such as sketches or dimensions, depending on the size and complexity of each particular project.

- How to use them to create detailed engineering drawings

Drawing Standards for Engineering Drawings

Drawing standards are used to ensure that all engineers are using the same standards for drawing.

There are different types of engineering drawings:

- Detailed engineering drawings show the design or product intent and detail the specifications or parameters (such as dimensions, tolerances, and materials). These drawings are important for manufacturing production. The drawing is made up of lettering, lines, and symbols that indicate specifications.

- Summary engineering drawings show basic engineering information about a part or assembly such as size, shape, and function but don’t go into as much detail as detailed engineering drawings do. They might also include some simple sketches of parts and illustrations.

How to Read an Engineering Drawing

You should use the same terminology as the engineer when referring to components. If you are using a drawing for design, it is important that you understand the engineer’s intent for how each part should fit together. This helps you avoid costly mistakes and rework.

When reading an engineering drawing, begin by looking at its title block. This section provides essential information about the drawing, including:

- Sheet number or identification data (that is, whether this is sheet 1 or 3 of 5)

- Title of project or project name (for example “Project Chevy”)

- Drawing scale(s) used for all views shown on that sheet(s) (for example ¼ inch = 1-foot scale used throughout)

After reading through this basic information, examine each view in more detail:

- Read all dimensions carefully; do not assume they are always true-to-scale unless noted otherwise in small print above each dimension block such as “Tolerance +0-.010” which means that although most dimensions may be accurate within 10%, some may vary by up to 10% from what you see on paper due to tolerances.

Detailed engineering drawings are important for manufacturing design and production. Engineers rely on detailed drawings in order to prepare parts and assemblies for manufacturing, as well as to communicate with other engineers working on product development.

In a friendly tone: “Engineers rely on detailed engineering drawings in order to prepare parts and assemblies for manufacturing, as well as to communicate with other engineers working on the product development. Detailed engineering drawings are also used by suppliers during the manufacturing process, helping ensure that all parties involved understand exactly what’s being delivered.”

Conclusion

There you have it! Detailed engineering drawings are a vital part of product development and design, which means that they can be useful for many different careers, from engineering to manufacturing. Using this information will help you understand how your work

will fit into the big picture—and it may even make your job easier! We hope this information has been helpful to you in understanding how detailed engineering drawings work and why they’re important for manufacturing products.